CNC MILLING | CNC TURNING

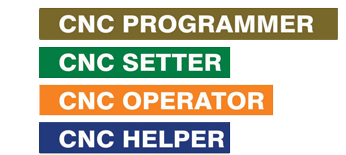

CAREER PATH

Advanced syllabus

2On the job training

3Campus interview

4job

பயிற்சி பெற்ற அணைவருக்கும் நேர்முக தேர்வின் மூலம் 100% மிக சிறந்த கம்பெனிகளில் நிரந்தர பணி பெற்று தருகிறோம்

Eligiblity

- BASIC EDUCATION

- ITI

- DIPLOMA

- BE

Duration of the course

- 30 DAYS - FULL TIME

- 45 DAYS - PART TIME

Class Timings

- Regular Class Timings : Morning : 10.00 am TO 01.00 pm Afternoon : 02.00 pm TO 04.00 pm Evening : 06.00 pm TO 08.00 pm

- Weekend Classes Timing : Morning : 10.00am TO 02.00 pm

CNC Turning | CNC Milling

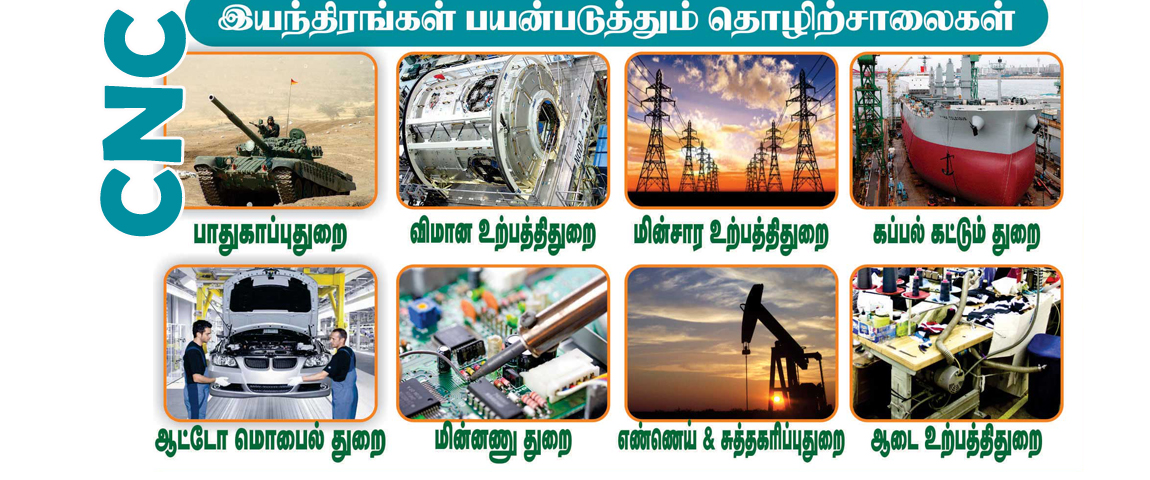

MANUFACTURING

- In the fast growing mechanical industry, The computer numerical control(CNC) is the latest advanced technology. In the Past 20 years The Person's Who have a good Knowledge and Experience in C.N.C are have a fast growrh in their life. Most of the Manufacturing industries are presently involves themselves CNC Machines for their Rapid Production For those purpose study of CNC Programming is very, very essential for youth to develop their future. To develop the youth’s future, ”PRIM Institute of Technology” Conduct a CNC Programming Course with live machine practical for said above factor

- CNC Turning - Syllabus - Machine operating | Tool selection &tool setting | Part Programming | Trouble shooting | Work holder selection | Drawing symbols | Cutter radius compensation with imaginary tool direction. | Threading Cycle | Taper Threading | Drilling Cycle | Pattern Repeating Cycle | Tapping Cycle | Grooving Cycle | Multiple Thread Cutting | Scroll Thread Cutting | Multistart Thread. | Profile calculation | Advance Macro programming

- CNC Milling - Syllabus- (VMC/HMC) | Machine operating | Tool setting& Tool selection | Part Programming | Trouble shooting | Fixture selection | Drawing symbols | Thread milling | Plane selection | Advanced Macro Programming | Scaling | Rotating | Mirroring | Up Milling & Down Milling with Cutter Radius Compensation. | Data Input Setting. | Local Work Co-ordinates setting | Rigid Tapping. | Automatic Corner Over ride | Single directing Position